Embarking on a journey into the world of pellets? This is your starting point Our detailed guide will reveal everything you need to know about these versatile fuel alternatives. From understanding the different types of pellets to choosing the best ones for your needs, we've got it all.

- Prepare yourself to a world of efficient and eco-friendly heating!

- Explore the benefits of pellets over other fuel sources.

- Become proficient in pellet stove maintenance for optimal performance.

We'll exploring the diverse world of pellet fuels and their individual traits. From wood pellets to corn pellets, we'll analyze each type, emphasizing their strengths and weaknesses.

Types and Applications of Pellets

Pellets represent a versatile type of material with widespread applications in diverse industries. Mainly, pellets comprise small, cylindrical fragments that get manufactured through the binding of raw materials. These constituents can differ from organic sources like wood, plant matter to synthetic elements such as minerals. The specific characteristics of pellets arise from their compact structure and the properties of the original materials.

Therefore, pellets discover applications in broad range of fields. In the construction industry, wood pellets are regularly used as a environmentally friendly alternative energy. Agricultural practices make use of pellets as a rich source of fertilizers. In the manufacturing sector, pellets serve as important building blocks in the manufacture of various goods. Moreover, pellets are investigated for their potential in sustainable fuel production, adding to their growing role in a coming focused on eco-friendliness.

The Pellet Making Process: From Start to End

Producing pellets, those cylindrical feed staples for livestock and pets, demands a multifaceted process that transforms raw materials into a consistent, high-quality product. It all more info begins with identifying the optimal raw feedstocks, which often comprise wood waste, agricultural residues, or even recycled paper. These substances are meticulously processed through a series of steps that include grinding, drying, and pelletizing.

Within the pelletizing process, the prepared materials are forced into cylindrical designs using high-pressure machinery. This creates a dense, uniform product that is then tempered to achieve its final shape.

Checks are implemented during the entire process to ensure the final pellets meet stringent standards for size, density, and nutritional value. The finished product is then stored and distributed to livestock farmers, pet owners, and other end users.

Using Pellets as Fuel and Animal Feed: Benefits

Pellets offer a practical solution for both fuel and animal feed. As a fuel source, pellets are highly efficient, generating ample heat with minimal impact. Furthermore, pellets derived from organic materials offer a sustainable alternative to traditional fossil fuels. In the realm of animal feed, pellets provide a balanced source of proteins, boosting livestock performance. This efficient form of feed reduces waste and simplifies the consumption process.

Keeping Pellet Fuel Tips

When storing pellets for your heating system, proper handling and storage are essential for maintaining their quality and ensuring optimal performance. First, choose a ventilated storage area that is protected from moisture and extreme temperatures. Consider using a dedicated pellet storage shed or bin to safeguard your pellets from the elements.

Ensure to keep pellets off the floor to prevent them from absorbing moisture. Use pallets, skids, or shelves to elevate the pellets. Additionally, avoid storing pellets near open flames or any other potential fire hazard.

It's also important to handle pellets with caution to avoid dust and contamination. Use a scoop or shovel designed for pellet handling to transfer pellets between containers. Avoid kicking pellets, as this can damage the pellets and increase dust generation.

For optimal storage, store pellets in tightly sealed containers or bags to minimize moisture absorption and pest infestation. Label stored pellets with the date of purchase and type of fuel for easy identification.

Regularly inspect your pellet storage area for signs of moisture or pests.

Address any issues promptly to prevent damage to your pellets and ensure safe operation of your heating system.

Understanding Pellet Density and Moisture Content

Pellet density and moisture content represent crucial elements in the effectiveness of wood pellets. Density, calculated as kilograms per cubic meter, reflects the compactness of the pellet material. A more substantial density generally leads to enhanced burn characteristics, like increased heat output and reduced ash production.

Moisture content, expressed as a percentage of the pellet's weight, impacts combustion efficiency and preservation. Minimal moisture content is optimal burn properties, minimizing smoke production and enhancing overall heat generation.

Understanding the interplay between these parameters is crucial for identifying suitable pellets for various applications and achieving efficient and environmentally friendly combustion.

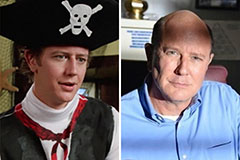

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!